The processing of the compressor is carried out while maintaining high product quality and speed in delivery times.

In addition to offering great economic advantages, the regenerated spare part has a positive effect on the environment as the pollution caused by the scrapping of cars is greatly reduced.

Since remanufacturing preserves much of the material in the original product, less raw material is used than in the production of new products. This is especially beneficial when the product contains critical raw materials - materials where there is a supply risk.

By limiting the amount of raw material extracted / recycled and the production of new components, remanufacturing typically uses less energy than producing a new product. A reduction in energy consumption is usually accompanied by a reduction in CO 2 emissions.

1. PULLEY DISASSEMBLY

2. PULLEY REBUILD

3. SANDBLASTING PULLEY

4. PULLEYS

5. SANDBLASTING COMPRESSOR

6. DISASSEMBLY

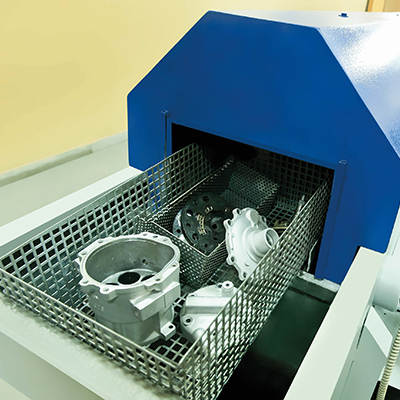

7. WASHING TUNNEL

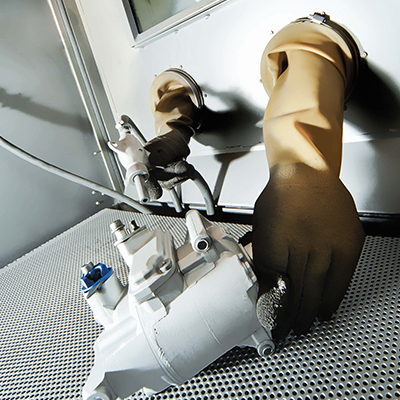

8. MANUAL WASHING

9. COMPRESSOR ASSEMBLY

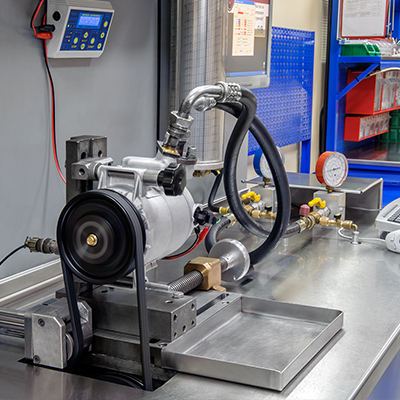

10. HELIUM TEST

11. PULLEY ASSEMBLY

Italiano

Italiano